- Europe

- Americas

- Asia and Middle East

- Africa and Oceania

Robotic tool changer for specific applications: From material handling to assembly and inspection

Table of content

1. Introduction

A. Introduction to the importance of welding applications in the industry

In the modern industry, welding applications are indispensable for the manufacturing of high-quality products. Whether in the automotive industry, mechanical engineering, or aerospace – welding permanently connects materials and ensures a safe and durable joint of components. The quality of welded joints directly affects the functionality and longevity of the final products.

With the advancement of automation technology, robots have established themselves as central elements in welding processes. They not only enable an increase in performance but also ensure consistently high quality of the welded joints. A decisive factor in this is the flexibility of robots to efficiently handle various welding tasks with different tools. This is where robotic tool changing systems come into play, allowing quick and precise swapping between different welding tools, thereby significantly boosting productivity and quality in manufacturing.

In this article, we will highlight the various applications of robotic tool changing systems in the field of welding technology, discuss the advantages and challenges of automated tool changing systems, and present technological solutions that optimize efficiency and quality in welding processes.

B. Tool changing for welding applications – combining precision and speed

In industrial welding technology, every second counts – and each welding process imposes specific requirements on the tool being used. From spot welding to arc welding to specialized procedures: Modern production lines need to remain flexible to efficiently execute various welding techniques.

Robotic tool changing systems play a key role in this. They allow for changing between different welding guns or other welding tools within seconds, without significantly delaying the production process. The result: higher productivity, reduced downtime, and consistently high welding quality due to the repeatability of robotic tool changing systems.

How exactly such systems work, what challenges they solve, and what technological innovations are employed will be discussed further in this article.

2. Applications of robotic tool changers for welding application

A. Different joining processes

In industrial manufacturing, especially in automotive production, there are numerous joining techniques to connect components. In addition to welding, common joining processes include riveting, screwing, punch riveting, adhesive bonding, clinching, flow drilling screws, and bending. Each of these methods has its own technical requirements and applications.

Welding is one of the most commonly used methods, as it creates permanent, high-strength joints that can withstand strong mechanical stresses. In sectors such as the automotive and aerospace industries, however, multiple joining processes are often required within a single production line. For instance, body structures are welded, while other components are further processed using riveting or adhesive bonding.

To efficiently handle this variety of processes, robots need to be able to flexibly switch between different tools. Robotic tool changers allow providing various joining tools within a single work cycle – without manual retooling times. This not only increases productivity but also optimizes the quality of the joining techniques.

B. Different welding processes

Welding processes are as versatile as their applications. From arc welding to MIG/MAG and TIG welding to laser welding – each method brings specific advantages and applications.

Spot welding plays a special role, especially in the automotive and sheet metal processing industries. In this process, components are joined by accurately placed weld points. Since different requirements are imposed on the welding process depending on the material and thickness of the components, a quick and reliable tool change is essential.

B1. Spot welding and the necessity of different tools

Spot welding is one of the key processes in industrial manufacturing, especially in automotive and sheet metal processing. Through targeted, short-term application of heat, sheets are connected at points – quickly, reliably, and with high strength. The weld point forms where the greatest resistance occurs, namely between the metal sheets to be welded.

The challenges lie in the variety of welding tasks: Different material thicknesses, component geometries, and production requirements necessitate the use of various welding guns and sizes.

To access hard-to-reach areas in the car body, special welding gun geometries may be necessary.

An efficient production process therefore requires quick adaptation to changing demands. Here, tool changing becomes a decisive factor: It ensures that the welding robot always works with the appropriate end effector – without delays and without loss of quality.

B2. Importance of tool changing

Efficient tool changing is a central success factor in automated welding processes. Especially in spot welding, but also in other welding methods, robots must switch between different tools within the shortest time to flexibly respond to different component geometries, material thicknesses, and production requirements.

Without automation, either a separate robot would be required for each welding gun, or manual retooling would have to be performed – a time-consuming and error-prone process that can significantly disrupt the production flow. Precise, automated changing of spot welding guns, torches, or other welding tools, however, minimizes downtime and significantly increases productivity.

In addition to pure efficiency enhancement, a reliable tool change also contributes significantly to quality assurance. Depending on the workpiece and material, the use of specialized tools can achieve consistent weld points with optimal force and energy distribution.

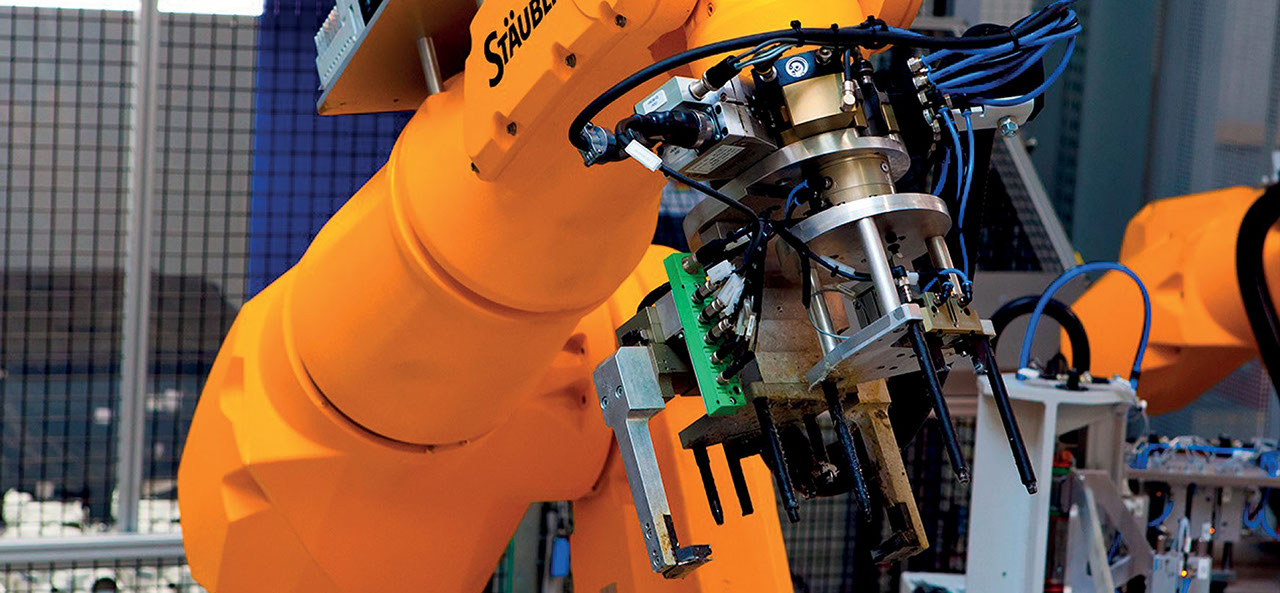

Modern robotic tool changers, as developed by Stäubli, for example, can not only change mechanical tools but also ensure media, energy, and data transmission in a single process. This allows complex welding applications to be automated without restrictions – for flexible, economical, and future-proof manufacturing.

C. Advantages and challenges of automatic robotic tool changers

Automatic robotic tool changers are a crucial component for optimizing welding applications. They enable quick, precise, and safe changes between different end effectors, thereby increasing efficiency, flexibility, and quality. However, their implementation also brings some challenges.

Advantages of automatic robotic tool changers

- Maximized productivity: Tool changes occur within seconds, drastically reducing downtime. Robots can perform different welding tasks without interruption.

- Increased flexibility: A robot can work with different welding guns or torches to handle various components and materials within a production line.

- Consistent quality: Extremely precise repeatability of the robotic tool changing systems ensures that the reproducibility and quality of the welded joints are consistently maintained.

- Reduced wear: As the appropriate tool is used for each task, the wear of individual components is reduced, lowering maintenance costs.

- Increased safety: Automated tool changers reduce the need for manual intervention and minimize the risk of operator errors or injuries due to improper handling.

Challenges in implementation

- Investment costs: The acquisition of an automatic tool changer requires an investment, which can quickly pay off through increased efficiency and lower maintenance costs.

- Integration complexity: The implementation of a tool changing system requires precise coordination with the existing robot control and thoughtful planning of the tool interfaces.

- Space requirements: In tight production environments, adequate space must be planned for the tool storage stations and the freedom of movement of the robot.

- Maintenance and compatibility: Although tool changers reduce the wear of individual components, the changing mechanisms themselves must be regularly checked and maintained. Additionally, compatibility with the welding tools and media connections used must be ensured.

D. Practical examples: Here, robotic tool changers demonstrate their advantages

The use of robotic tool changers in welding applications is particularly advantageous where a high variance of components, materials, or welding processes is required. The following concrete examples from the industry show how automated tool changing systems increase productivity, reduce downtime, and improve the quality of welded joints.

1. Automotive industry: Body construction with variable welding guns

In vehicle production, robots must set thousands of weld points every day – often on components with varying material thicknesses and geometries. Here, the quick change between different spot welding guns is crucial, as each gun is optimized for specific requirements (e.g., different electrode shapes or gun sizes for narrow or wide weld points). Aluminum welding is also regularly used in lightweight construction.

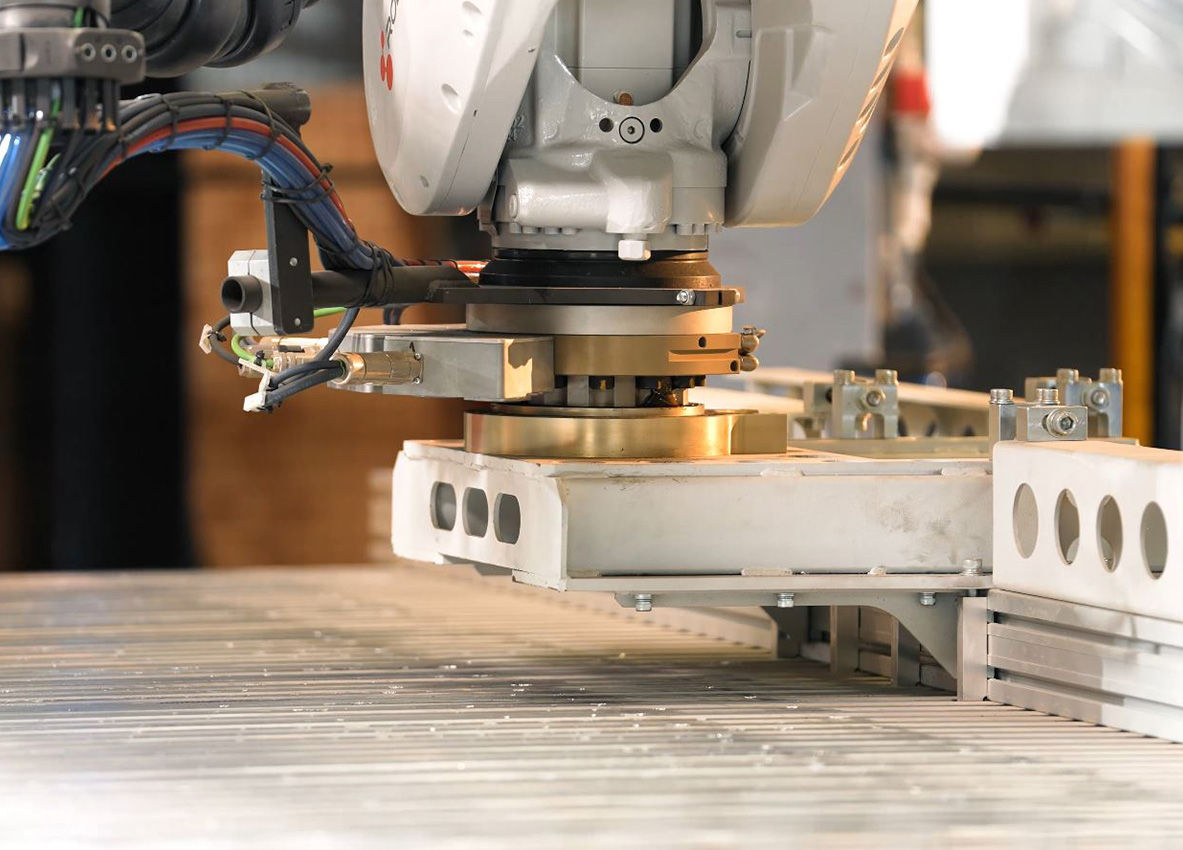

2. Mechanical engineering: Combination of welding and milling

In the manufacturing of complex mechanical engineering components, welding and machining steps are often combined. An example is the production of steel frames for construction machinery or rail vehicles, where welding is followed by post-processing weld seams through milling or grinding.

3. Aerospace: Precision welding of aluminum structures

In the aerospace industry, lightweight materials such as aluminum or titanium are often used, requiring special welding processes (e.g., TIG or laser welding). Additionally, components with complex geometries must be welded precisely. A robot equipped with a tool changer can switch between different welding torches to use various methods depending on the component. This ensures high weld seam quality and makes the entire production process more flexible.

4. Rail vehicle construction: Adaptation to different material thicknesses

In the manufacturing of train carriages or locomotives, various steel alloys with different wall thicknesses are processed. While precise spot welds are required for thinner sheets, MIG/MAG welding methods are more suitable for thicker sections. Instead of using different robots for different tasks, a single robot with a tool changer can switch between a spot welding gun, a MIG welding torch, and clamping tools. This enables flexible manufacturing and reduces the number of robots needed.

5. Steel and metal construction: Switching between welding and cutting

In the steel construction and metal processing industry, welding and cutting processes are often combined to fabricate parts from large steel plates. A robot can seamlessly switch between a plasma cutter and a welding torch by using a tool changer. This enables it to make precise cuts and then weld the cut parts directly, without requiring manual intervention from an operator.

3. Conclusion

A. Summary of key points

Robotic tool changers have established themselves as key technology in automated welding technology. They enable quick and precise changes between different welding tools, optimizing productivity, flexibility, and quality. Especially in the automotive industry, mechanical engineering, and aerospace, they are indispensable for designing complex manufacturing processes efficiently and economically. In addition to increased efficiency, they contribute to the reduction of downtime, quality assurance, and occupational safety.

B. Future prospects

The future of robotic tool changers lies in intelligent, connected systems that enable even higher automation and flexibility. Wireless data and energy transmission, as well as adaptive, sensor-based systems, will enable even more seamless integration into manufacturing processes. Predictive maintenance through integrated sensors will help avoid unplanned downtime and maximize system lifespan.

C. Developments

Current developments focus on energy-efficient locking systems that require no external media supply, as well as modular tool changers that can adapt to changing production requirements. Providers like Stäubli are driving these innovations to provide companies with powerful, future-proof solutions for their welding applications. Thus, robotic tool changers are not only an efficiency improvement for today’s production environments but also a key technology for the factory of the future. Systems like the MPS series from Stäubli offer modular and highly precise solutions that enable tool changes not only mechanically but also with integrated media, energy, and data transfer. This allows even the most demanding welding applications to be implemented safely and efficiently.

More topics in focus

Our topics serve as your comprehensive resource for understanding the critical role of robot tool changers in enhancing efficiency across a multitude of applications.

Discover our innovative solutions - Download exclusive brochures now!

Stäubli is a leading technological pioneer in the construction and development of robotic tool-changing systems solutions.

Discover the versatility and efficiency of Stäubli's advanced robotic tool-changing systems by downloading our showcases of innovative solutions.

Success Stories

Find out our solutions and customer testimonials!

-

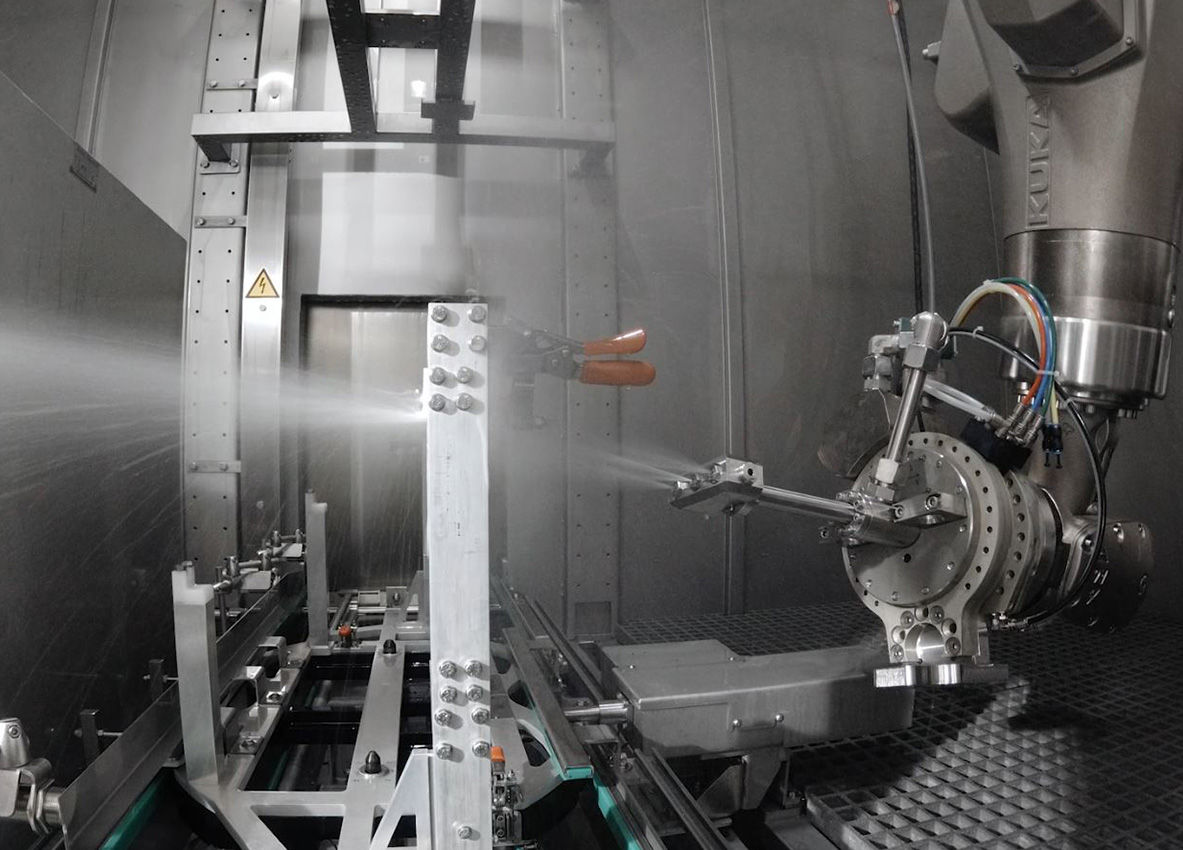

Silberhorn - Industrial Machinery

Component cleaning for metalworking in the tightest of spaces - Robot tool change in the wet cell. -

Volvo Trucks - Automotive

Provide robot tool change systems which meet Volvo’s demanding reliability target. -

Robinova / Teksan - Industrial Machinery

A field proven solution which saves time, improves robot utilization, and enhances operator safety. -

Miele - Industry Machine & Equipments

Miele opted for the modularity and efficiency of the MPS 130 systems with the Stäubli robots to develop their dishwasher lines production.